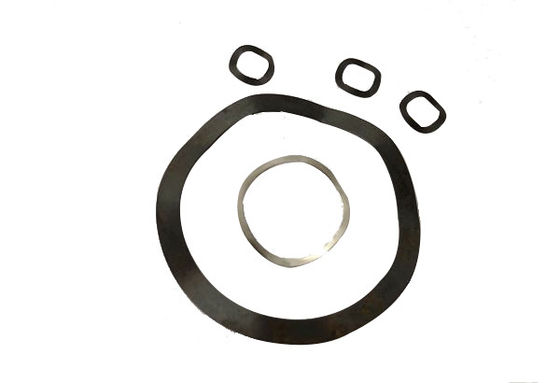

Black E - Coating gasket ring with curve shape applied in car shock absorbers

Specifications:

| Material |

P/M Copper and Copper Alloys |

| P/M Iron and Carbon Steel |

| Iron And Carbon Steel |

| Iron-Copper And Copper Steel |

| Sinter Hardened Steel |

| Commix Low Alloy Steel |

| Surface treatment |

Sand Blasting |

| Zinc/Chrome Plating |

| Rust-preventive treatment (steaming treating) |

| Painting |

| Electrophoresis |

| Powder Coating |

Description:

Xia Yi is specializing in powder metallurgy, shock absorber pistons, PTFE products and different parts used

in automobile and motorcycle. Our company has a technical team to research and develop the automatic

machines. Our products spread out all over the country, and we supply components to Korea, America and

Japan. Our products are well known at home and abroad with a good reputation.

Powder metallurgy products

Shock absorber rod guide with du bearing

1. XIA YI is a professional powder metallurgy manufacturer.

2. Process: mixing--compacting--sintering--resizing--cleaning--vacuum oiling--packing

3. Material: steel, copper, steel copper, bronze, alloy.

4. High precision, 100% quality assurance with competitive price

5. We can make the products according to customers' drawings or requirement.

6. Short deliver time.

7. The products we produce are widely used in automobile, motorcycle and many other fields: like

transmission gear, spur gear, bevel gear, helical gear, sleeve, copper sleeve, sleeve bearing, bushing,

bush, pulley, timing pulley, structural parts, powder metallurgy parts, nut, sintered parts, auto parts, rotor

and stator etc.

Manufacturability:

1. Auto Mechanical Press: 50T, 100T, 140T

2. Hydraulic Press: 100T, 315T, 600T, 800T

3. Sinter furnaces, including one harden Sinter Furnace

4. Heat treatment: Carbonitriding quenching and high frequency quenching

5. Ultrasonic clearing and auto de-burring

6. In-house tooling making: EDM, wire cutting machine

7. Strength in machining: Machine center, CNC milling, CNC lathe, two end lapper etc

Test Ability:

1. Carbon sulfur determinator

2. Metallurgic microscope

3. Hydraulic universal material tester

4. Hardness testers

5. Pneumatic measuring instrument

6. Measuring projector

7. Gear testing instrument

8. Electrical profile meter

Welcome to visit our company!

We will show your our best quality and service!

Applications:

1. Automotive Part

2. Motorcycle Part

3. Pump Parts

4. Locomotive Parts

5. Machinery Parts

6. Tool Parts

Competitive Advantage:

High quality guarantee:

(1) Electronic balance ensure density

(2) Test equipments to ensure crushing strength

(3) QC an PQC to ensure close tolerance and accurate dimension

Design ability:

Develop different models of gear, bearing, bushing, structural parts etc. can produce according to

drawings or samples.

Picture show:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!