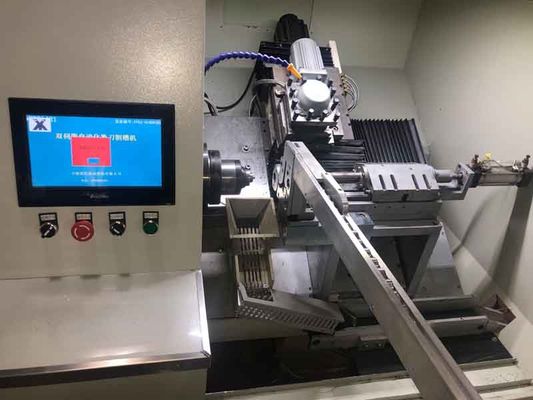

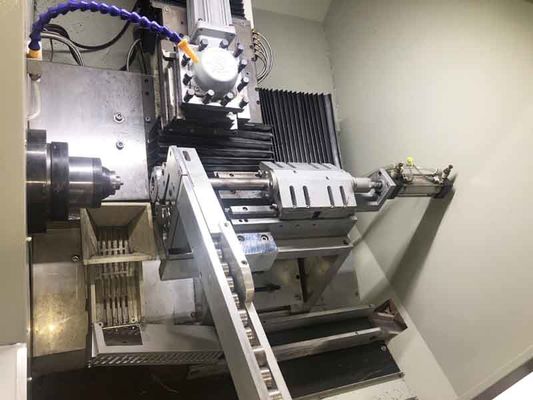

Full Automatic Shock Piston Grooving Making Machine With Various Process

Technical parameters

| Items |

Technical parameters |

| Machine name |

CNC automatic groove cutting machine |

|

Dimensions(L*W*H)

(Excluding feeding & ejection)

|

2400mm×2200mm×1600mm |

| Weight |

1500kg |

| Rated voltage |

380V |

| Rated frequency |

50Hz |

| Max power |

5kw |

| Lathe |

CNC |

| Control system |

CNC built-in program +PLC |

| Precision |

0.01mm |

| Max speed for mainshaft |

3000RPM |

| Products |

Cutting grooves for pistons or used as a conventional CNC lathe |

| Feeding system |

Vibrating plate + automatic recognition flip |

| Ejection system |

Conveyor belt + rotating plate |

| Cycle time |

3-10 s/pcs(based on process demanded) |

TEAM: We have a technical team to develop automatic and semi-automatic machines.

DIMENSION: We can get the pistons with PTFE banding on OD and can highly improve work efficiency

and lower the cost. Infrared ray can control the piston's outer dimension and we can assure the

dimension's consistency.

MOULD: We can make the mould by ourselves.

OPERATORS: Only need to put the powder metallurgy products on the table and take out of the finished

pistons from the table.

One person can operate several machines.

To assure the appearance of the products, we will improve to use long conveyer directly to work table

If you are interested in such machines, we can offer the detail information if you need. Our technical

persons can help to set up and debug the machines.

Our technic persons can help to set up and debug the machines.

Output:500-600 pcs pistons/hour

Electricity:380V

Tooling set up:15 minutes

Piston diameter:25mm-46mm

Piston height:12mm-20mm

Machine lead time:2 months

Tooling lead time:3 weeks

Machinery spares:2 weeks

Machinery spare set:available

Pistons in /out:on table

Infrared ray can control the piston's outer dimension and we can assure the dimension's consistency.

MOULD: We can make the mould by ourselves.

OPERATORS: Only need to put the powder matallurgy products on the table and take out of

the finished pistons from the table.

One person can operate several machines.

Banding ring pictures:

Competitive advantage:

superior hard chrome piston finish

maximum safety and stability

available for different types of vehicles

customer own design available

optimum corrosion resistance

superior design and engineering

Application:

All sinter pistons with different size

Picture show

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!