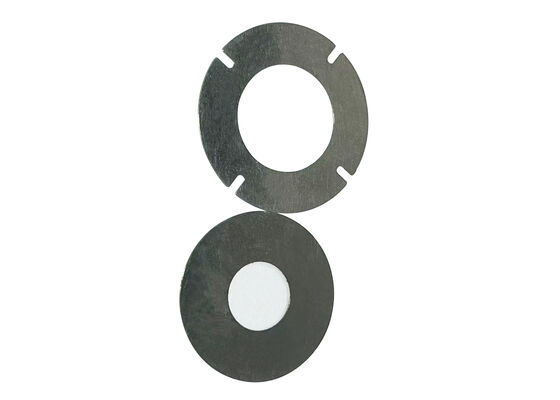

Product Description:

The Shock Valve Shims are essential components designed specifically for use in high-performance shock absorber parts, providing precision, durability, and optimal functionality. Manufactured with strict adherence to OEM dimensions, these shims ensure a perfect fit within various shock absorber assemblies, contributing to the overall efficiency and longevity of suspension systems. Whether you are upgrading your vehicle’s suspension or replacing worn-out parts, these shock valve shims offer a reliable solution that meets demanding industry standards.

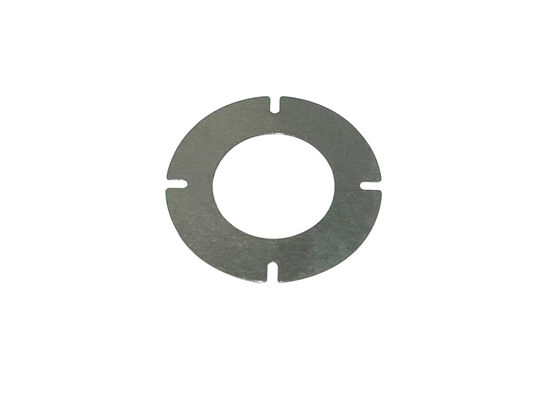

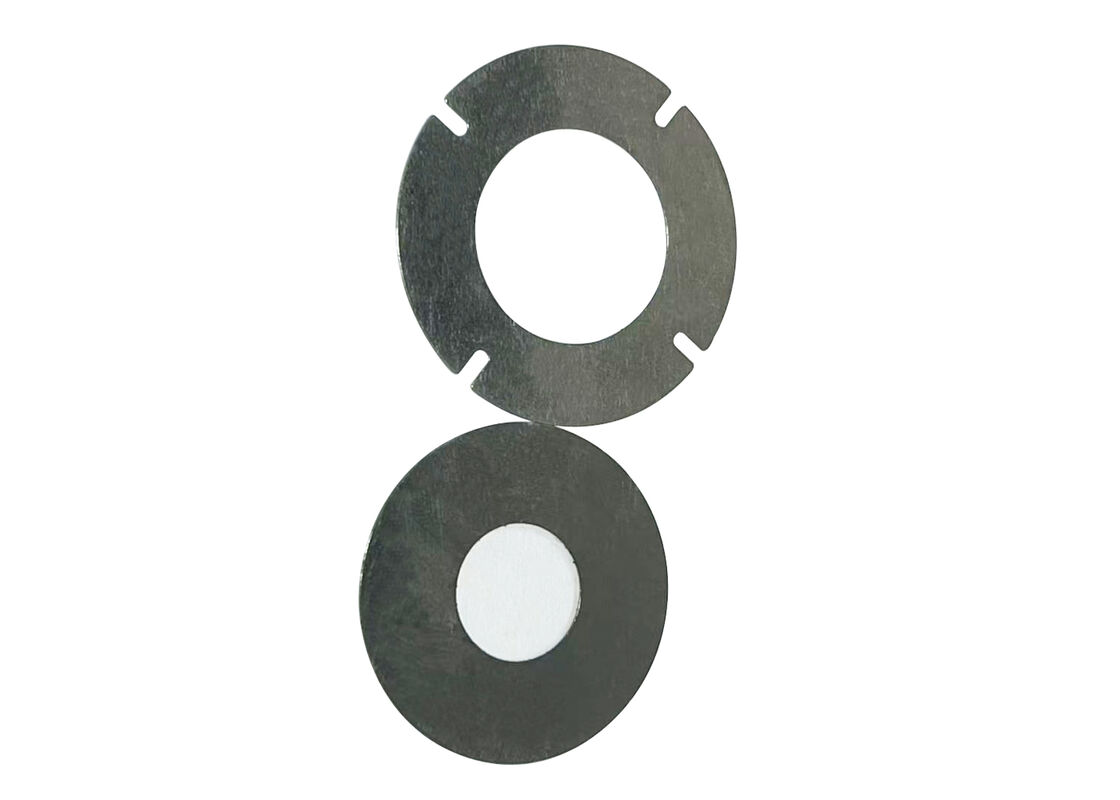

One of the standout features of our Shock Valve Shims is their polished surface finish. This polished finish not only enhances the aesthetic appeal but also reduces friction between moving parts, ensuring smoother operation and minimizing wear over time. The meticulous polishing process improves the interaction between the shims and other shock absorber parts, such as retaining rings, thereby increasing the lifespan of the entire assembly. This attention to detail is crucial in maintaining consistent performance, especially in high-stress automotive or industrial applications.

Dimensionally, our Shock Valve Shims are crafted to meet exact OEM specifications. This precision manufacturing guarantees compatibility with a wide range of shock absorber models, eliminating the guesswork often associated with aftermarket parts. By maintaining OEM dimensions, these shims ensure seamless integration with existing components, including retaining rings that hold the valve shims securely in place within the shock absorber assembly. This precise fitment is vital for maintaining the integrity and functionality of the shock absorber system.

Durability and strength are critical when it comes to shock absorber parts, and our Shock Valve Shims excel in this regard with a hardness rating between HRC 40-60. This hardness range indicates a balanced combination of toughness and wear resistance, enabling the shims to withstand the repeated compressive forces and vibrations experienced during vehicle operation. The robust hardness ensures that the shims resist deformation and maintain their structural integrity, which is essential for the consistent performance of shock absorbers over extended periods.

The manufacturing process for these shims involves advanced milling or machining techniques, allowing for precise control over their thickness and overall geometry. Milling or machining ensures that each shim is produced to exact tolerances, which is critical for maintaining the delicate balance of forces within the shock absorber valve system. This precision machining process also facilitates customization options, enabling the production of shims tailored to specific performance requirements or unique vehicle applications.

Another important consideration when selecting shock absorber parts is the lead time, and our Shock Valve Shims typically have a sample time of 10-15 days. This relatively short turnaround period allows for efficient prototyping, testing, and integration into your shock absorber assemblies without unnecessary delays. Whether you are a manufacturer needing quick samples for quality verification or a workshop seeking fast replacement parts, this timely delivery supports streamlined operations and project timelines.

In addition to their primary function, these shock valve shims work in conjunction with retaining rings, which are critical for holding the shims securely in place within the shock absorber assembly. The combination of high-quality shims and reliable retaining rings ensures that all components remain properly aligned and function harmoniously under dynamic conditions. This collaboration between parts helps maintain the shock absorber’s ability to absorb impacts effectively, providing enhanced ride comfort and vehicle stability.

In summary, our Shock Valve Shims represent a high-quality, precision-engineered solution for anyone seeking dependable shock absorber parts. With polished surfaces, exact OEM dimensions, a hardness rating of HRC 40-60, and manufacturing via milling or machining processes, these shims deliver outstanding performance and durability. Coupled with retaining rings, they form an integral part of shock absorber systems, ensuring reliable operation under demanding conditions. The efficient sample time of 10-15 days further enhances their appeal, making them an excellent choice for automotive professionals and enthusiasts alike.

Features:

- Product Name: Shock Valve Shims

- Type: Punching machine

- Sample Time: 10-15 days

- Surface Finish: Polished for enhanced durability

- Inspection Process: IQC, IPQC, FQC, QA to ensure high quality

- Size Range: Available from 8mm to 500mm

- Compatible with Washer Shim and Retaining Rings applications

- Designed specifically as Shock Valve Shims for precise performance

Technical Parameters:

| Craft |

Stamping |

| Size |

8mm To 500mm |

| Shape |

Round |

| Surface Finish |

Polished |

| Sample Time |

10-15 days |

| Inspection |

IQC, IPQC, FQC, QA |

| Technology |

Etching Or Stamping, Line Cutting |

| Standard |

GB/DIN/JIS/ANSI |

| Features |

Lightweight, Durable |

| Weight |

Lightweight, Varies By Size |

Applications:

Shock Valve Shims are precision-engineered components designed to enhance the performance and reliability of hydraulic and pneumatic systems. Manufactured by OEM and aftermarket suppliers, these shims are produced under strict quality controls and are ISO9001:2008 certified, ensuring consistent quality and durability. With a polished surface finish and advanced manufacturing technologies such as etching or stamping and line cutting, XIAYI Valving Shims provide excellent dimensional accuracy and smooth operation within valve assemblies.

These shock valve shims are ideal for applications requiring precise adjustment and fine-tuning of valve clearances, making them indispensable in industries such as automotive, aerospace, industrial machinery, and heavy equipment. Their hardness rating of HRC 40-60 guarantees superior wear resistance and longevity, even under high-pressure and high-impact conditions. The availability of sizes ranging from 8mm to 500mm allows for versatile use across various valve designs and configurations.

In practical scenarios, XIAYI Valving Shims are commonly used alongside retaining rings and washer shims to secure and stabilize valve components, preventing unwanted movement and ensuring optimal sealing performance. For instance, in shock absorbers and hydraulic valves, these shims help regulate fluid flow and pressure by fine-tuning the valve stack, thus improving system responsiveness and reducing noise or vibration.

The polished surface finish of the shims minimizes friction and wear against adjacent parts, extending the service life of the entire valve assembly. Whether employed in repair, maintenance, or new equipment manufacturing, XIAYI shock valve shims serve as critical elements that enhance operational efficiency and reliability. Their precise thickness and hardness make them the preferred choice for technicians and engineers who demand high-quality valving shims that perform consistently under demanding conditions.

Additionally, the compatibility of XIAYI shims with retaining rings and washer shims ensures seamless integration within complex valve stacks, enabling easy installation and replacement during servicing. This makes them perfect for applications that require frequent adjustments or calibration, such as hydraulic control valves, shock absorbers, and other mechanical systems where precise valve timing and fluid control are crucial.

Customization:

XIAYI offers customized Shock Valve Shims designed to meet your specific requirements. Our Shock Absorber Parts are manufactured with precision stamping craft, ensuring high quality and durability. Certified under ISO9001:2008, our Washer Shim products comply with standards including GB, DIN, JIS, and ANSI. With a hardness range of HRC 40-60, these shims provide excellent performance and reliability. They are engineered to withstand temperature resistance from -40°C to 150°C, making them ideal for demanding applications. Sample delivery time is typically between 10-15 days, allowing for efficient prototyping and testing.

Support and Services:

Our Shock Valve Shims are designed to provide precise control and tuning for your suspension system. For technical support, please ensure you have the product model and specifications available when seeking assistance. We offer detailed installation guides and tuning advice to help you achieve optimal performance. Our team of experts is ready to assist with troubleshooting and customization to meet your specific needs. Regular maintenance and correct installation are crucial for the longevity and effectiveness of the shims. Please refer to the product manual for detailed instructions and recommendations.

Packing and Shipping:

Shock Valve Shim is carefully packaged to ensure protection during transit. The shims are placed in a durable plastic bag to prevent any damage or contamination. The packaging is then securely sealed and labeled with product details for easy identification.

For shipping, Shock Valve Shims are packed in sturdy boxes with adequate cushioning materials to avoid movement and impact. We use reliable shipping services to guarantee timely and safe delivery to your doorstep. Tracking information is provided for all shipments to keep you updated on your order status.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!