Product Description:

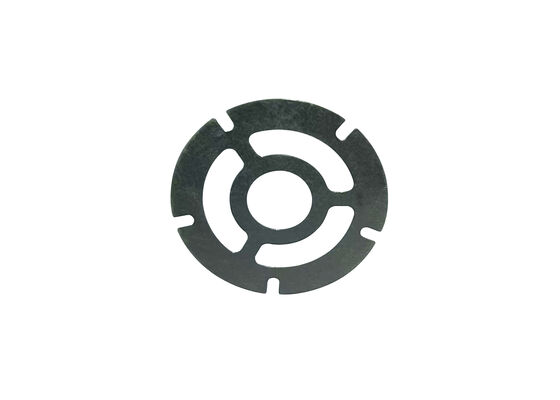

The Shock Valve Shims are precision-engineered components designed to enhance the performance and reliability of shock absorbers in various automotive and industrial applications. Manufactured by trusted OEM and aftermarket suppliers, these shims are crafted with a focus on durability, lightweight construction, and exceptional hardness, making them an essential component in the assembly and maintenance of shock valve systems.

One of the standout attributes of these Shock Valve Shims is their hardness, rated between HRC 40-60. This range ensures that the shims provide excellent resistance to wear and deformation, even under high-stress conditions. The hardness is carefully controlled during the manufacturing process to deliver optimal performance, ensuring that the shims can withstand the rigorous demands of shock valve operation over prolonged periods.

In addition to their hardness, these shims are remarkably lightweight. This feature is crucial in applications where weight reduction is a priority, such as in high-performance vehicles and precision machinery. The lightweight nature of the shims contributes to the overall efficiency of the shock valve system by reducing inertia and enabling quicker response times. Despite their lightness, the shims do not compromise on strength or durability, providing a reliable solution that balances performance with longevity.

Durability is further enhanced by the shims’ ability to resist temperature variations ranging from -40°C to 150°C. This wide temperature resistance makes the Shock Valve Shims suitable for use in environments with extreme thermal conditions, whether in cold climates or high-heat industrial settings. The materials and manufacturing techniques employed ensure that the shims maintain their structural integrity and functional properties across this temperature spectrum, thereby reducing the risk of failure due to thermal stress.

These shims are designed to work seamlessly with other critical components such as Retaining Rings and Trim Rings, which are often integral parts of shock valve assemblies. The precise dimensions and consistent quality of the Shock Valve Shims ensure a perfect fit and smooth interaction with these parts, promoting optimal sealing and valve operation. This compatibility is vital for maintaining the overall efficiency and reliability of the shock absorber system.

Manufacturers and suppliers of these shims prioritize quality control and timely delivery. Customers can expect sample availability within 10-15 days, allowing for prompt evaluation and integration into production lines or repair processes. This efficient sample turnaround time supports rapid prototyping and testing, enabling engineers and technicians to verify performance characteristics before committing to larger orders.

Whether sourced from OEM manufacturers or reputable aftermarket suppliers, the Shock Valve Shims meet stringent industry standards and specifications. Their robust construction, combined with lightweight and temperature-resistant properties, make them an indispensable part for anyone looking to enhance their shock valve systems. By incorporating these shims into your assemblies, you ensure improved durability, consistent performance, and extended service life of your shock absorbers.

In summary, the Shock Valve Shims offer a high-hardness, lightweight, and durable solution tailored to withstand a broad range of temperatures from -40°C to 150°C. Their compatibility with Retaining Rings and Trim Rings, coupled with reliable supply from OEM and aftermarket sources, positions them as a top choice for automotive and industrial shock valve applications. With a sample delivery time of just 10-15 days, these shims provide both quality and convenience, meeting the demanding needs of modern shock absorber systems.

Features:

- Product Name: Shock Valve Shims

- Weight: Lightweight, varies by size

- Shape: Round

- Size Range: 8mm to 500mm

- Inspection Standards: IQC, IPQC, FQC, QA

- Manufacturing Technology: Etching or Stamping, Line Cutting

- Ideal for use in Shock Absorber Components

- Compatible with Retaining Rings and Trim Ring applications

Technical Parameters:

| Manufacturer |

OEM Or Aftermarket Suppliers |

| Type |

Milling Or Machining |

| Size |

8mm To 500mm |

| Craft |

Stamping |

| Inspection |

IQC, IPQC, FQC, QA |

| Standard |

GB/DIN/JIS/ANSI |

| Features |

Lightweight, Durable |

| Sample Time |

10-15 days |

| Temperature Resistance |

-40°C To 150°C |

| Surface Finish |

Polished |

Customization:

XIAYI offers customized Shock Valve Shims designed to meet the highest standards of quality and performance. Manufactured under IATF16949 certification, our shims are produced using precise milling or machining techniques to ensure optimal fit and functionality. These Valving Shims are engineered to withstand temperature ranges from -40°C to 150°C, making them ideal for various Shock Absorber Components. Our products comply with GB, DIN, JIS, and ANSI standards, guaranteeing compatibility and reliability. Each shim undergoes rigorous inspection processes including IQC, IPQC, FQC, and QA to maintain superior quality. The surface finish is polished to provide excellent durability and smooth operation, perfectly complementing Retaining Rings and other critical parts in your shock absorber assemblies.

Support and Services:

Product Technical Support and Services for Shock Valve Shims include comprehensive assistance to ensure optimal performance and longevity of the product. Our support team provides detailed installation guidance, maintenance tips, and troubleshooting advice tailored to your specific application.

We offer expert consultation to help you select the correct shim sizes and configurations that best suit your shock absorber setup. Additionally, technical documentation and application notes are available to assist with precise adjustments and performance tuning.

For after-sales service, we provide warranty support and replacement options to guarantee customer satisfaction. Our commitment is to deliver reliable technical support to maximize the efficiency and durability of your Shock Valve Shims.

Packing and Shipping:

Shock Valve Shims are carefully packaged to ensure it arrives in perfect condition. The shims are placed in a protective plastic bag and then secured within a sturdy cardboard box to prevent any damage during transit.

We use reliable shipping services with tracking options available for all orders. Standard shipping typically takes 3-7 business days, while expedited shipping options are also offered for faster delivery.

For international orders, please allow additional time for customs processing. We take great care in packaging to minimize the risk of shipping delays or damage, ensuring your Shock Valve Shims reach you safely and promptly.

FAQ:

Q1: What brand manufactures the Shock Valve Shims?

A1: The Shock Valve Shims are manufactured by the brand XIAYI.

Q2: Are the XIAYI Shock Valve Shims certified?

A2: Yes, the XIAYI Shock Valve Shims are certified with IATF16949.

Q3: What is the primary use of Shock Valve Shims?

A3: Shock Valve Shims are used to adjust and fine-tune the performance of shock absorbers in vehicles and machinery.

Q4: Can the XIAYI Shock Valve Shims be used with various types of shock absorbers?

A4: Yes, XIAYI Shock Valve Shims are designed to be compatible with a wide range of shock absorber models.

Q5: How do I know which size of Shock Valve Shim to use?

A5: The appropriate size of Shock Valve Shim depends on your specific shock absorber model and desired damping characteristics. Refer to your shock absorber’s specifications or consult with a professional for guidance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!