Product Description:

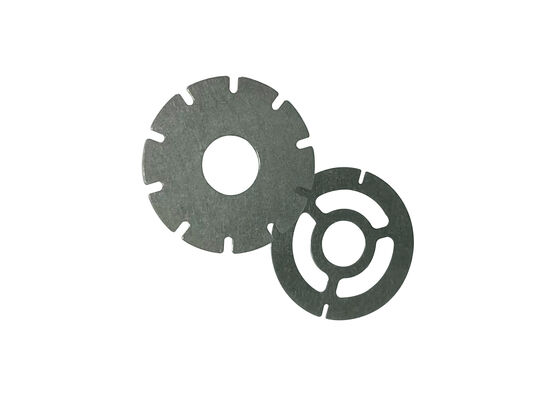

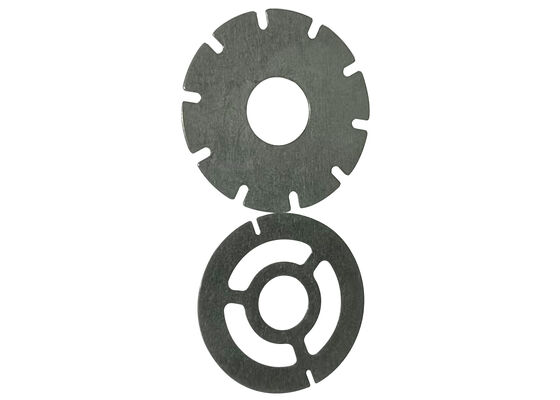

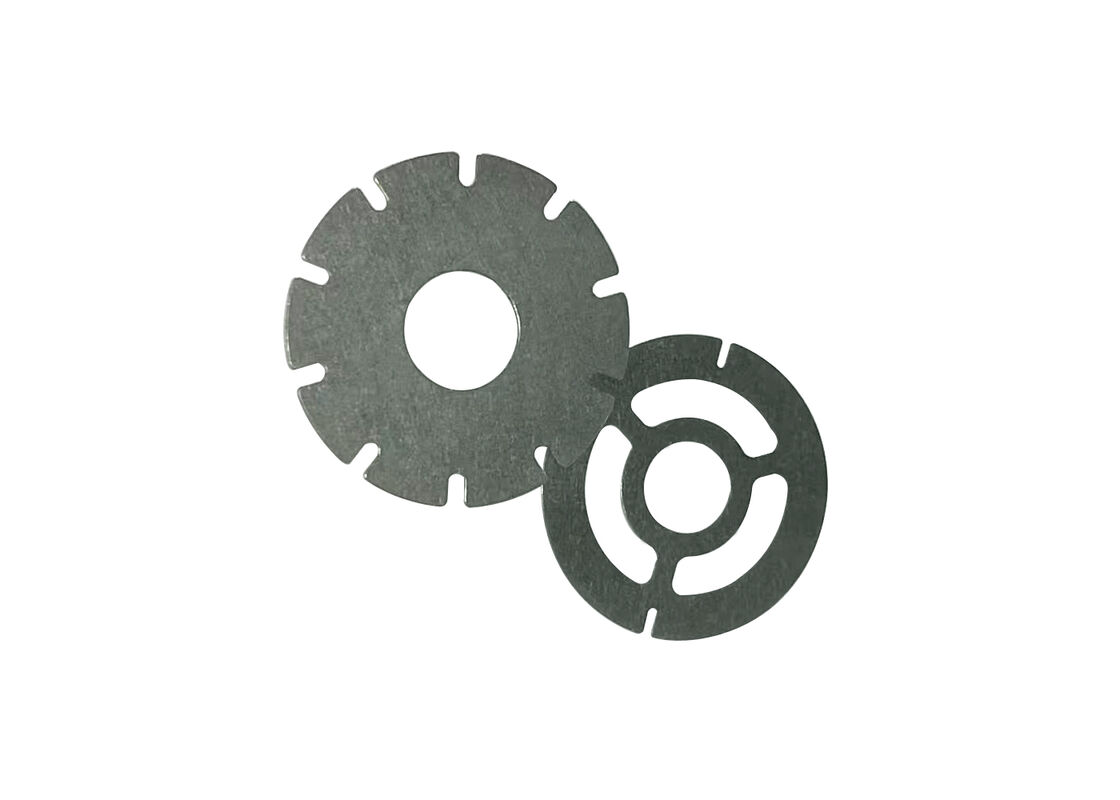

The Shock Valve Shims are precision-engineered components designed to enhance the performance and reliability of shock absorbers in various automotive and industrial applications. These shims serve as critical valving shims within the shock absorber assembly, playing a vital role in controlling fluid flow and damping characteristics to provide optimal shock absorption and ride comfort.

Crafted with meticulous attention to detail, the Shock Valve Shims feature a polished surface finish that not only ensures a smooth and consistent operation but also enhances durability by reducing friction and wear during use. The polished finish contributes to the overall efficiency of the shock absorber components, allowing for precise and responsive movement under varying load conditions.

One of the standout characteristics of these shims is their lightweight construction, which varies by size to meet specific application requirements. The lightweight design aids in reducing the overall weight of the shock absorber assembly without compromising strength or performance. This balance is essential for maintaining vehicle agility and fuel efficiency, especially in high-performance and off-road vehicles.

Dimensionally, the Shock Valve Shims are manufactured to meet OEM specifications, ensuring seamless integration with existing shock absorber systems. Their round shape is optimized for uniform pressure distribution and consistent valve operation, which is crucial for maintaining the longevity and reliability of the shock absorber components. The precise dimensions guarantee compatibility with a wide range of metal ring gasket assemblies, further enhancing their versatility in various mechanical setups.

As integral parts of shock absorber components, these valving shims work in conjunction with metal ring gaskets to create a sealed environment that controls hydraulic fluid movement within the shock absorber. This collaboration between the shims and gaskets is essential for fine-tuning the damping force, enabling smoother rides and improved handling characteristics. The metal ring gasket complements the shims by providing a secure seal that prevents fluid leakage, thereby maintaining consistent shock absorber performance over time.

The manufacturing process for the Shock Valve Shims includes a sample lead time of 10-15 days, allowing for customization and quality checks to meet specific client requirements. This timeframe ensures that each batch of shims undergoes rigorous inspection to uphold high standards of precision and reliability. Customers can expect timely delivery without compromising on the quality or performance of the product.

In summary, the Shock Valve Shims are essential valving shims that contribute significantly to the functionality and efficiency of shock absorber components. Their polished surface finish, lightweight build, OEM dimensions, and round shape make them an ideal choice for enhancing shock absorber systems across a variety of applications. When paired with metal ring gaskets, these shims form a crucial part of the damping mechanism that ensures superior shock absorption, improved vehicle stability, and a comfortable ride experience.

Whether you are looking to improve the performance of existing shock absorbers or require reliable components for new assemblies, these Shock Valve Shims offer a high-quality solution that meets stringent industry standards. Their precise engineering and durable construction make them indispensable in the realm of shock absorber technology, providing both manufacturers and end-users with confidence in their shock absorber systems.

Features:

- Product Name: Shock Valve Shims

- Craft: Stamping

- Standard: GB / DIN / JIS / ANSI

- Size Range: 8mm to 500mm

- Sample Time: 10-15 days

- Hardness: HRC 40-60

- Suitable for use as Metal Ring Gasket, Valving Shims, and Washer Shim

Technical Parameters:

| Sample Time |

10-15 days |

| Craft |

Stamping |

| Dimension |

OEM |

| Shape |

Round |

| Size |

8mm to 500mm |

| Standard |

GB/DIN/JIS/ANSI |

| Temperature Resistance |

-40°C to 150°C |

| Weight |

Lightweight, Varies By Size |

| Manufacturer |

OEM or Aftermarket Suppliers |

| Features |

Lightweight, Durable |

Applications:

The XIAYI Shock Valve Shims are precision-engineered components designed to optimize the performance and reliability of various mechanical and hydraulic systems. These valving shims, available in sizes ranging from 8mm to 500mm, are manufactured using advanced etching or stamping and line cutting technologies, ensuring exceptional accuracy and consistency. The polished surface finish not only enhances durability but also reduces friction, making these washer shims ideal for high-demand applications.

One of the primary application occasions for XIAYI Shock Valve Shims is in automotive shock absorbers and suspension systems. Here, the valving shims play a critical role in controlling fluid flow and damping characteristics, which directly impact ride comfort and vehicle stability. By precisely adjusting the thickness and configuration of washer shims, technicians can fine-tune shock absorbers to meet specific performance requirements, whether for everyday driving, off-road adventures, or high-performance racing scenarios.

In addition to automotive uses, these washer shims are widely employed in industrial machinery and hydraulic equipment where precise valve regulation is essential. The XIAYI brand’s commitment to quality is evident in its ISO9001:2008 certification, ensuring that every batch undergoes rigorous inspection stages including IQC (Incoming Quality Control), IPQC (In-Process Quality Control), FQC (Final Quality Control), and QA (Quality Assurance). This meticulous quality management guarantees reliability and longevity in critical applications.

Furthermore, the versatility of XIAYI Shock Valve Shims allows them to be used in aerospace, marine, and heavy equipment industries where vibration damping and valve performance are paramount. The stamping craft utilized in their production provides robustness and uniformity, which are crucial for maintaining consistent valve operation under extreme conditions. Whether used as valving shims or washer shims, these components contribute significantly to reducing wear and enhancing the efficiency of hydraulic valves.

Overall, XIAYI Shock Valve Shims serve as essential components in any scenario requiring precise valve control and shock absorption. Their broad size range, advanced manufacturing techniques, polished finish, and stringent inspection processes make them the preferred choice for engineers and technicians aiming to achieve optimal system performance and reliability.

Customization:

At XIAYI, we offer comprehensive product customization services for Shock Valve Shims to meet your specific requirements. Our Shock Valve Shims are manufactured in compliance with ISO9001:2008 certification, ensuring high quality and reliability. We provide a wide range of dimensions tailored to OEM standards, guaranteeing perfect fit and performance for your applications.

Our shims are designed to withstand extreme temperature conditions, with excellent temperature resistance ranging from -40°C to 150°C. Crafted with a hardness of HRC 40-60, these shims deliver optimal durability and strength while remaining lightweight, with weight varying by size to suit your needs.

In addition to Shock Valve Shims, we also specialize in customizing Retaining Rings and Trim Rings, adhering to recognized standards including GB, DIN, JIS, and ANSI. Whether you require standard or bespoke solutions, XIAYI ensures precision engineering and superior material quality to enhance the performance of your assemblies.

Packing and Shipping:

Product Packaging: The Shock Valve Shims are carefully packaged in a durable, protective plastic case to prevent damage during transit. Each shim is securely placed to avoid movement and scratching. The packaging includes a detailed instruction sheet to guide proper installation and usage.

Shipping: We ensure fast and reliable shipping for all Shock Valve Shims orders. Products are shipped in sturdy outer boxes with adequate cushioning materials to protect against impact. Tracking information will be provided upon dispatch, and expedited shipping options are available for urgent needs. We ship worldwide with trusted carriers to guarantee timely delivery.

FAQ:

Q1: What is the Shock Valve Shims product used for?

A1: The Shock Valve Shims by XIAYI are designed to precisely adjust the valve clearance in shock absorbers, ensuring optimal performance and durability.

Q2: Is the XIAYI Shock Valve Shims product certified?

A2: Yes, the product is certified under IATF16949:2016, which guarantees high quality and manufacturing standards.

Q3: What materials are used in the XIAYI Shock Valve Shims?

A3: XIAYI Shock Valve Shims are made from high-grade, durable materials to withstand high pressure and maintain consistent performance over time.

Q4: How do I know which shim thickness to use?

A4: The appropriate shim thickness depends on your specific shock absorber model and clearance requirements. XIAYI provides detailed specifications to help you select the correct shim.

Q5: Can the XIAYI Shock Valve Shims be used with all types of shock absorbers?

A5: While XIAYI Shock Valve Shims are compatible with a wide range of shock absorbers, it is recommended to check the compatibility with your specific shock model before purchase.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!