Product Description:

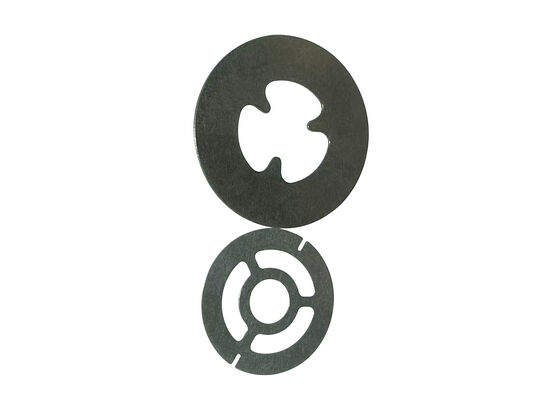

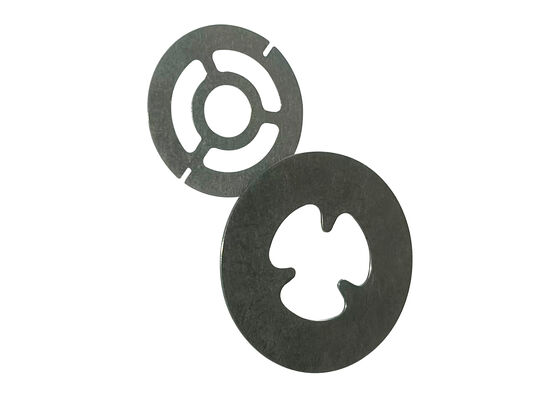

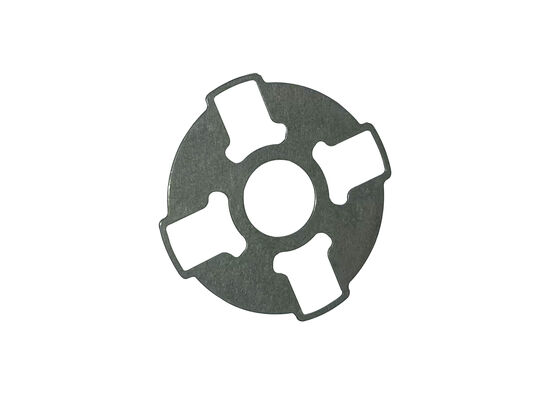

Shock Valve Shims are essential components in the realm of automotive and industrial applications, particularly in the assembly and maintenance of shock absorbers. Designed to provide precise control over fluid flow within shock absorbers, these shims play a critical role in ensuring optimal damping performance and ride comfort. Manufactured to meet various international standards such as GB, DIN, JIS, and ANSI, Shock Valve Shims are versatile and reliable components suitable for a wide range of shock absorber systems.

One of the key features of Shock Valve Shims is their availability in a broad size range, from as small as 8mm to as large as 500mm. This extensive size range allows these shims to be used in numerous applications, from compact automotive shock absorbers to large industrial damping systems. The dimensions of these shims can also be customized according to OEM specifications, ensuring seamless integration with original equipment or aftermarket parts. This flexibility makes Shock Valve Shims a preferred choice among manufacturers and repair specialists who demand high precision and compatibility.

In addition to their size and dimensional variety, Shock Valve Shims are lightweight components, with their weight varying depending on their size and material composition. This lightweight characteristic contributes to the overall efficiency and performance of the shock absorber by reducing unnecessary mass without compromising durability or functionality. The balance of strength and lightness is crucial for maintaining the responsiveness and longevity of shock absorber parts.

Shock Valve Shims are often used in conjunction with other critical shock absorber parts such as Retaining Rings. Retaining Rings serve to secure and position the shims within the shock valve assembly, preventing displacement or misalignment during operation. The precise fit and function of Retaining Rings and Shock Valve Shims together ensure the shock absorber performs reliably under various conditions, including high stress and dynamic loads.

These shims are manufactured by both OEM and aftermarket suppliers, providing customers with a wide selection of options depending on their quality requirements and budget considerations. OEM manufacturers typically produce Shock Valve Shims that adhere strictly to original equipment specifications, guaranteeing compatibility and performance equivalent to the original parts. On the other hand, reputable aftermarket suppliers offer shims that meet or exceed industry standards, often providing cost-effective alternatives without sacrificing quality.

Shock Valve Shims are critical for controlling the damping characteristics of shock absorbers by managing the flow of hydraulic fluid through the valve system. By adjusting the thickness and stack configuration of these shims, engineers can fine-tune the shock absorber’s resistance and responsiveness, achieving the desired balance between comfort and control. This adjustability makes Shock Valve Shims indispensable in the design and maintenance of advanced suspension systems used in automobiles, motorcycles, and various machinery.

Overall, Shock Valve Shims are indispensable shock absorber parts that combine precision engineering, customizable dimensions, and adherence to international standards such as GB, DIN, JIS, and ANSI. Their lightweight nature and compatibility with Retaining Rings further enhance their functionality within the shock absorber assembly. Whether sourced from OEM manufacturers or trusted aftermarket suppliers, these shims offer reliable performance and durability essential for maintaining the efficacy of shock absorbers in diverse applications.

Features:

- Product Name: Shock Valve Shims

- Dimension: OEM standard dimensions ensuring perfect fit

- Type: Manufactured through precision milling or machining processes

- Size Range: Available in sizes from 8mm to 500mm

- Weight: Lightweight design, weight varies by size

- Hardness: High durability with HRC 40-60 hardness rating

- Suitable for use as Valving Shims in shock absorber systems

- Essential Shock Absorber Parts for optimal performance

- Compatible with Retaining Rings for secure assembly

Technical Parameters:

| Inspection |

IQC, IPQC, FQC, QA |

| Standard |

GB / DIN / JIS / ANSI |

| Manufacturer |

OEM Or Aftermarket Suppliers |

| Technology |

Etching Or Stamping, Line Cutting |

| Type |

Milling Or Machining |

| Surface Finish |

Polished |

| Features |

Lightweight, Durable |

| Weight |

Lightweight, Varies By Size |

| Sample Time |

10-15 days |

| Size |

8mm To 500mm |

Applications:

The XIAYI Shock Valve Shims are precision-engineered components designed to enhance the performance and reliability of various hydraulic and pneumatic systems. Crafted using advanced stamping techniques and finished with a polished surface, these shims ensure exceptional durability and consistency. Certified under IATF16949:2016, XIAYI guarantees quality and precision in every piece, making them an ideal choice for demanding industrial applications.

These round-shaped valving shims are widely used as essential components in shock absorbers, valves, and other fluid control devices. Their primary function is to provide precise spacing and fine-tuning of valve components to optimize flow control and pressure regulation. The ability to customize these shims through etching, stamping, and line cutting technologies allows for exact thickness and dimension control, ensuring compatibility with various valve assemblies.

One of the key application occasions for XIAYI Shock Valve Shims is in the manufacturing and maintenance of trim rings and metal ring gaskets. In these scenarios, the shims act as critical spacers that help achieve the perfect fit and seal, enhancing the overall performance of the gasket or ring. This is particularly important in automotive shock absorbers, industrial machinery, and aerospace components where precision and reliability are paramount.

Maintenance and repair workshops also benefit greatly from these valving shims. When repairing or refurbishing hydraulic valves or shock absorbers, technicians rely on XIAYI shims to replace worn or damaged ones, restoring the original functionality and extending the lifespan of the equipment. The relatively quick sample time of 10-15 days allows for efficient prototyping and testing, facilitating faster turnaround in production and repair cycles.

In summary, XIAYI Shock Valve Shims serve a vital role in applications requiring high precision and durability. Whether integrated into trim rings, metal ring gaskets, or as standalone valving shims, their polished surface finish, innovative manufacturing craft, and strict quality certification make them indispensable in various industrial and mechanical scenarios. Their versatility and reliability ensure they meet the stringent demands of modern engineering and maintenance tasks.

Customization:

At XIAYI, we offer customized product customization services for Shock Valve Shims to meet your specific requirements. As an IATF16949 certified manufacturer and trusted OEM or aftermarket supplier, we ensure the highest quality standards in every piece. Our Shock Valve Shims are available in sizes ranging from 8mm to 500mm, providing versatility to suit various applications. Manufactured through precise milling or machining processes, these metal ring gasket components are lightweight yet durable, guaranteeing reliable performance. Whether you need a metal ring gasket tailored for enhanced shock absorption or specialized valve shim configurations, XIAYI delivers durable and lightweight solutions designed to your exact specifications.

Packing and Shipping:

Product Packaging: The Shock Valve Shims are carefully packaged in a durable, protective bag to prevent any damage during transit. Each set is securely sealed and labeled with product details and specifications for easy identification. The packaging is compact and designed to minimize environmental impact while ensuring the shims remain clean and free from contaminants.

Shipping: We offer reliable shipping options to ensure your Shock Valve Shims arrive promptly and in perfect condition. Orders are processed within 1-2 business days and shipped via trusted carriers with tracking available. International shipping is available with estimated delivery times varying by destination. Proper cushioning and handling procedures are followed to maintain product integrity throughout the shipping process.

FAQ:

Q1: What brand manufactures the Shock Valve Shims?

A1: The Shock Valve Shims are manufactured by XIAYI, a reputable brand known for quality automotive components.

Q2: Are the Shock Valve Shims certified for quality?

A2: Yes, the Shock Valve Shims are certified under IATF16949, ensuring they meet international quality management standards.

Q3: What is the primary use of Shock Valve Shims?

A3: Shock Valve Shims are used to adjust the damping characteristics of shock absorbers, improving vehicle suspension performance.

Q4: Can XIAYI Shock Valve Shims be used with different shock absorber models?

A4: XIAYI Shock Valve Shims are designed to be compatible with a variety of shock absorbers, but it is recommended to check specific fitment details for your model.

Q5: How do I know which size of Shock Valve Shim to use?

A5: The correct size of Shock Valve Shim depends on your shock absorber specifications and desired damping settings. Refer to the product documentation or consult a professional for guidance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!