Product Description:

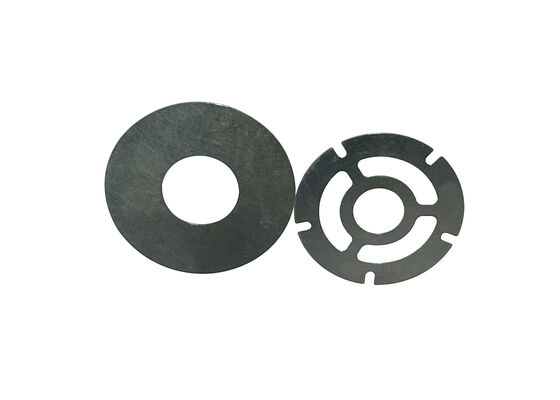

The Shock Valve Shims are precision-engineered components designed to enhance the performance and reliability of shock valve systems across various industrial applications. Crafted with a focus on durability and lightweight construction, these shims offer an optimal solution for maintaining the precise spacing and alignment required in high-performance shock absorbers and related assemblies. By integrating advanced manufacturing techniques and high-quality materials, the Shock Valve Shims deliver exceptional strength and resilience, ensuring they withstand the demanding conditions often encountered in mechanical and hydraulic systems.

One of the standout features of these Shock Valve Shims is their impressive hardness, rated between HRC 40-60. This level of hardness provides a robust resistance to wear and deformation, making them ideal for environments where consistent performance under stress is critical. The shims maintain their structural integrity even when subjected to continuous pressure and mechanical forces, which is essential for prolonging the lifespan of shock valve components and minimizing maintenance requirements.

In addition to their hardness, these shims boast a polished surface finish that not only enhances their aesthetic appeal but also contributes to their functional efficiency. The smooth, polished surface reduces friction between mating parts, which helps in minimizing wear and tear while promoting smoother operation of the shock valve mechanism. This refinement also aids in preventing corrosion and buildup of contaminants on the shim surface, further extending their service life.

Temperature resistance is another crucial attribute of the Shock Valve Shims. Engineered to perform reliably within a wide temperature range from -40°C to 150°C, these shims are suitable for use in extreme cold and heat conditions without compromising their mechanical properties. This temperature resilience ensures consistent performance in harsh environments, such as automotive, aerospace, and heavy machinery applications, where temperature fluctuations are common.

The manufacturing process for the Shock Valve Shims is highly efficient, with a sample delivery time of just 10-15 days. This quick turnaround enables manufacturers and engineers to expedite their prototyping and production cycles, ensuring that design iterations and final implementations are not delayed. The combination of rapid sample availability and superior product quality makes these shims an excellent choice for time-sensitive projects that require reliable components.

Moreover, the Shock Valve Shims are compatible with a range of complementary components, including Metal Ring Gaskets, Retaining Rings, and Washer Shims. This compatibility ensures seamless integration into complex assemblies, providing engineers with versatile options for customizing shock valve setups according to specific performance requirements. The Metal Ring Gasket works in tandem with the shims to create tight seals, preventing leakage and maintaining system pressure. Retaining Rings secure the shims and other components in place, ensuring stability during operation. Washer Shims offer additional spacing and alignment options, enhancing the overall precision and functionality of the shock valve assembly.

In summary, the Shock Valve Shims combine lightweight construction, exceptional durability, high hardness, polished surface finish, and broad temperature resistance to deliver a premium product tailored for demanding shock valve applications. Their quick sample turnaround time and compatibility with Metal Ring Gaskets, Retaining Rings, and Washer Shims further underscore their value in engineering and manufacturing contexts. Whether for enhancing shock absorber performance or optimizing mechanical assemblies, these shims represent a reliable and efficient solution that meets the rigorous demands of modern industrial use.

Features:

- Shock Absorber Components designed for optimal performance

- Lightweight Washer Shim ensures easy installation and handling

- Durable Retaining Rings provide long-lasting reliability

- Meets industry standards: GB, DIN, JIS, and ANSI

- Weight varies by size but remains lightweight for efficiency

- Temperature resistance range from -40°C to 150°C for versatile use

- Hardness rating of HRC 40-60 for enhanced durability and wear resistance

Technical Parameters:

| Hardness |

HRC 40-60 |

| Sample Time |

10-15 days |

| Size |

8mm To 500mm |

| Features |

Lightweight, Durable |

| Craft |

Stamping |

| Shape |

Round |

| Manufacturer |

OEM Or Aftermarket Suppliers |

| Technology |

Etching Or Stamping, Line Cutting |

| Temperature Resistance |

-40°C To 150°C |

| Inspection |

IQC, IPQC, FQC, QA |

Applications:

XIAYI Shock Valve Shims are essential components designed to enhance the performance and reliability of shock absorber systems across various applications. As certified under ISO9001:2008, these shims guarantee high-quality manufacturing standards, ensuring durability and precision in every piece. Manufactured by trusted OEM or aftermarket suppliers, the XIAYI Shock Valve Shims are crafted using advanced stamping techniques, resulting in lightweight yet robust parts that vary in weight according to size specifications. This adaptability makes them suitable for a wide range of shock absorber components, providing optimal fit and function.

In automotive repair and assembly, the XIAYI Shock Valve Shims serve as critical Metal Ring Gasket elements within shock absorbers. Their precise OEM dimensions allow seamless integration with existing suspension systems, improving shock absorption efficiency and vehicle handling. Whether used in passenger cars, trucks, or motorcycles, these shims ensure consistent performance by maintaining proper valve clearances and minimizing wear. Their lightweight nature contributes to overall vehicle weight reduction, which is an important factor in enhancing fuel efficiency and ride comfort.

Beyond automotive uses, these Metal Ring Gasket shims find application in industrial machinery and heavy equipment that rely on hydraulic shock absorbers. In manufacturing plants or construction sites, where shock absorber components endure high stress and frequent impact, XIAYI’s shims provide reliable sealing and cushioning. The rigorous inspection process, including IQC (Incoming Quality Control), IPQC (In-Process Quality Control), FQC (Final Quality Control), and QA (Quality Assurance), ensures every shim meets stringent quality criteria, minimizing downtime due to part failure.

Additionally, the XIAYI Shock Valve Shims are widely used in motorsports and off-road vehicles, where shock absorbers face extreme conditions. Their stamped metal construction and precise OEM dimensions allow for quick replacement and maintenance, supporting high-performance tuning and customization. This makes them indispensable for racing teams and enthusiasts aiming to optimize suspension responsiveness and durability.

Overall, the XIAYI Shock Valve Shims are versatile Metal Ring Gasket components that play a vital role in maintaining the integrity of shock absorber systems across diverse applications. Their certified quality, lightweight design, and meticulous inspection ensure dependable performance, making them a preferred choice for both OEM and aftermarket suppliers worldwide.

Customization:

XIAYI offers customized Shock Valve Shims designed to meet the highest standards of quality and performance. As a trusted manufacturer and supplier of Shock Absorber Parts, we specialize in producing precision Metal Ring Gasket and other Shock Absorber Components using advanced stamping craft combined with milling or machining techniques. Our products comply with international standards such as GB, DIN, JIS, and ANSI, ensuring compatibility and reliability. Certified with IATF16949:2016, XIAYI maintains rigorous inspection processes including IQC, IPQC, FQC, and QA to guarantee superior quality. Whether you require OEM or aftermarket solutions, our customization services are tailored to fulfill your specific requirements with excellence.

Support and Services:

Our Shock Valve Shims are engineered to provide precise control and optimal performance in hydraulic shock absorbers. Designed for durability and consistent operation, these shims help in fine-tuning the damping characteristics to match specific application requirements.

For technical support, our team of experts is available to assist with installation guidance, performance optimization, and troubleshooting. We offer detailed documentation and resources to ensure correct shim selection and integration within your shock system.

Additionally, we provide customization services to tailor shim thickness and material properties to your unique specifications. Our commitment is to deliver high-quality components that enhance the reliability and efficiency of your shock absorbers.

Please refer to the product manual for detailed installation instructions and maintenance tips to maximize the lifespan and effectiveness of the Shock Valve Shims.

FAQ:

Q1: What brand manufactures the Shock Valve Shims?

A1: The Shock Valve Shims are manufactured by the brand XIAYI.

Q2: Are the Shock Valve Shims certified for quality?

A2: Yes, the Shock Valve Shims are certified under IATF16949, ensuring high-quality standards.

Q3: What materials are used in XIAYI Shock Valve Shims?

A3: XIAYI Shock Valve Shims are made from durable, high-quality materials designed to withstand extreme pressure and wear.

Q4: Can these shims be used for different types of shock absorbers?

A4: Yes, XIAYI Shock Valve Shims are compatible with a wide range of shock absorbers, but it is recommended to check specific model compatibility.

Q5: How do Shock Valve Shims affect suspension performance?

A5: Shock Valve Shims help regulate the flow of hydraulic fluid within the shock absorber, improving damping characteristics and overall suspension performance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!