Product Description:

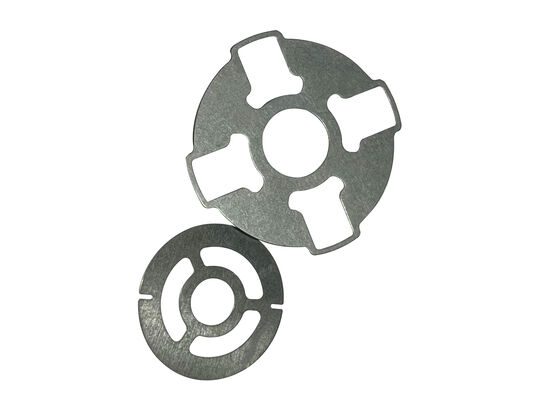

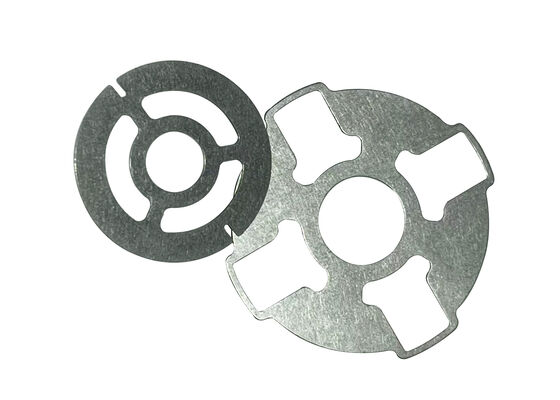

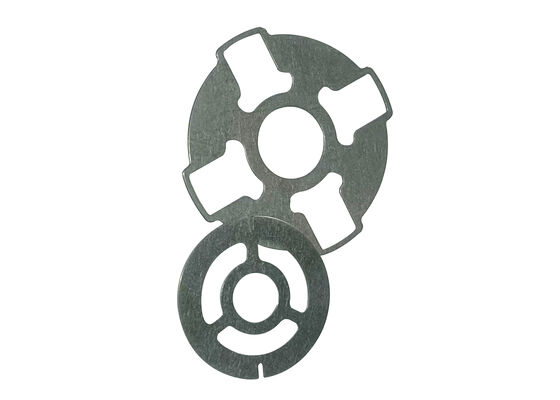

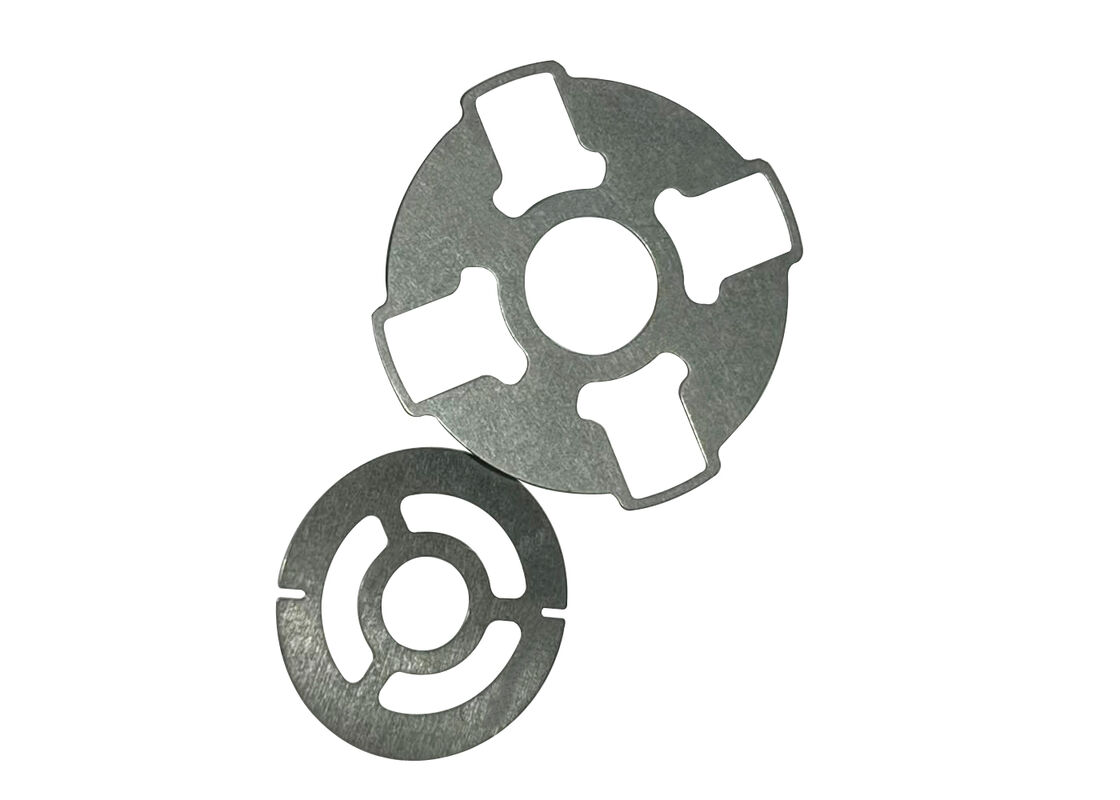

The Shock Valve Shims are precision-engineered components designed specifically for use in shock absorber systems, playing a crucial role in ensuring the optimal performance and durability of shock absorber parts. Manufactured through advanced milling or machining processes, these shims exhibit exceptional dimensional accuracy and surface finish, making them an indispensable element in the assembly of high-quality shock absorber components.

Crafted using the stamping technique, the Shock Valve Shims combine efficiency and precision, allowing for consistent production that meets stringent industry standards. The stamping process ensures that each washer shim maintains uniform thickness and shape, crucial for the reliable functioning of shock absorbers under varying operational stresses. This manufacturing method not only enhances the structural integrity of the shims but also contributes to cost-effective mass production without compromising quality.

One of the standout features of these Shock Valve Shims is their hardness rating, which ranges between HRC 40 and 60. This hardness level strikes the perfect balance between durability and flexibility, enabling the shims to withstand repeated compressive forces and frictional wear within the shock absorber assembly. The enhanced hardness ensures that the shims maintain their shape and performance over extended periods, thereby reducing maintenance frequency and prolonging the lifespan of shock absorber parts.

Quality assurance is a cornerstone of the production process for these washer shims. Comprehensive inspection protocols are implemented at various stages, including Incoming Quality Control (IQC), In-Process Quality Control (IPQC), Final Quality Control (FQC), and Quality Assurance (QA). These rigorous inspection procedures guarantee that every shim meets the highest quality standards, ensuring reliability and consistency in their application. By adhering to such meticulous quality control measures, manufacturers can confidently provide shock absorber components that deliver superior performance and safety.

The Shock Valve Shims conform to internationally recognized standards such as GB, DIN, JIS, and ANSI. Compliance with these standards underscores the product’s suitability for a wide range of applications across different industries and geographical regions. Whether used in automotive, industrial machinery, or other equipment requiring shock absorption, these shims provide dependable performance aligned with global quality benchmarks.

As essential shock absorber parts, these washer shims function as critical pressure-distributing elements within the valve assembly, helping to regulate fluid flow and damping characteristics. Their precise thickness and hardness ensure that the shock absorber components respond accurately to dynamic loads, thereby enhancing ride comfort, vehicle stability, and overall operational efficiency. The role of these shims extends beyond mere spacing; they contribute directly to the fine-tuning of shock absorber behavior, making them vital for high-performance shock absorber systems.

In summary, the Shock Valve Shims are expertly crafted washer shims produced through milling or machining and stamping processes, featuring a hardness of HRC 40-60. They undergo stringent inspections including IQC, IPQC, FQC, and QA, guaranteeing consistent quality and reliability. Built to comply with GB, DIN, JIS, and ANSI standards, these components are indispensable shock absorber parts that enhance the functionality and durability of shock absorber components. Their precision engineering and robust construction make them a preferred choice for manufacturers seeking dependable and high-performance shock absorber parts for diverse applications.

Features:

- Product Name: Shock Valve Shims

- Size Range: 8mm to 500mm

- Weight: Lightweight, varies by size

- Inspection Standards: IQC, IPQC, FQC, QA

- Temperature Resistance: -40°C to 150°C

- Surface Finish: Polished for enhanced performance

- Ideal for use in Shock Absorber Parts

- Compatible with Trim Ring assemblies

- Precision engineered Shock Valve Shims for optimal shock absorption

Technical Parameters:

| Shape |

Round |

| Dimension |

OEM |

| Standard |

GB / DIN / JIS / ANSI |

| Hardness |

HRC 40-60 |

| Features |

Lightweight, Durable |

| Type |

Milling Or Machining |

| Technology |

Etching Or Stamping, Line Cutting |

| Surface Finish |

Polished |

| Inspection |

IQC, IPQC, FQC, QA |

| Manufacturer |

OEM Or Aftermarket Suppliers |

Applications:

The XIAYI Shock Valve Shims are precision-engineered components designed to optimize the performance and longevity of hydraulic and pneumatic shock valve systems. Certified under ISO9001:2008, these shims undergo rigorous inspection processes including IQC, IPQC, FQC, and QA to ensure the highest quality and reliability. With a hardness rating of HRC 40-60, XIAYI Shock Valve Shims provide exceptional durability while maintaining a lightweight profile, making them ideal for various industrial and automotive applications.

One of the primary application occasions for XIAYI Shock Valve Shims is in the assembly and maintenance of shock absorbers where precise valve clearance adjustment is critical. The polished surface finish of these shims minimizes friction and wear, enhancing the smooth operation of the shock valve system. Their advanced manufacturing technology, involving etching or stamping combined with line cutting, guarantees consistent dimensional accuracy and fit, which is essential when working with components such as the Trim Ring that often require exact shim thicknesses for optimal performance.

In automotive repair shops and manufacturing plants, XIAYI Shock Valve Shims are frequently used during the rebuilding or fine-tuning of shock absorbers. They help adjust the preload and flow characteristics within the shock valve assembly, ensuring a balanced and responsive suspension system. The durability and lightweight nature of these shims also make them suitable for high-performance vehicles where weight reduction without compromising strength is a priority.

Additionally, these shims find application in industrial machinery that relies on shock valve mechanisms for vibration damping and load control. Their polished surfaces and precise etching or stamping technology facilitate seamless integration with other components, including the Trim Ring, thereby improving the overall system reliability and lifespan. Whether in heavy-duty equipment or precision instruments, XIAYI Shock Valve Shims provide consistent performance under demanding conditions.

In summary, the XIAYI Shock Valve Shims are versatile and dependable components designed for a wide range of settings—from automotive suspension systems to industrial shock valve assemblies. Their combination of 16949 certification, stringent quality inspections, hardness, lightweight design, and advanced surface finishing make them an excellent choice for professionals seeking high-quality shims that deliver superior performance and durability.

Customization:

XIAYI offers customized Shock Valve Shims designed to meet your specific requirements. As a trusted OEM or aftermarket supplier, we manufacture Metal Ring Gasket and Shock Valve Shims with precision and quality. Our products adhere to ISO9001:2008 certification standards, ensuring reliable performance and durability.

We provide Shock Valve Shims in dimensions tailored to OEM specifications, with sizes ranging from 8mm to 500mm. Our Metal Ring Gasket and shim materials are engineered to withstand temperature resistance from -40°C to 150°C, suitable for various industrial applications.

Each Shock Valve Shim and Metal Ring Gasket undergoes strict quality inspections, including IQC, IPQC, FQC, and QA processes, to guarantee the highest standards. Trust XIAYI for your customized Metal Ring Gasket and Shock Valve Shims needs, delivering exceptional quality and service.

Support and Services:

Our Shock Valve Shims are precision-engineered components designed to optimize the performance and durability of your shock absorbers. Manufactured from high-quality materials, these shims ensure consistent valve operation and enhanced shock response under various conditions.

Technical support for Shock Valve Shims includes detailed installation guides, maintenance tips, and troubleshooting assistance to help you achieve the best performance from your shock absorbers. Our experts are available to provide advice on shim selection, stack configuration, and valve tuning tailored to your specific application.

We also offer comprehensive services such as custom shim thickness fabrication, batch testing for quality assurance, and replacement part sourcing. Whether you are upgrading your suspension system or performing routine maintenance, our support and services are designed to meet your technical needs efficiently.

For optimal results, it is recommended to follow the provided installation instructions carefully and consult our technical resources for guidance on shim compatibility with different shock models. Regular inspection and proper handling of the shims will extend the life of your shock valve assembly and maintain peak shock absorber performance.

FAQ:

Q1: What brand manufactures the Shock Valve Shims?

A1: The Shock Valve Shims are manufactured by the brand XIAYI.

Q2: Are the Shock Valve Shims certified?

A2: Yes, the Shock Valve Shims are certified under IATF16949:2016.

Q3: What materials are used in XIAYI Shock Valve Shims?

A3: XIAYI Shock Valve Shims are made from high-quality, durable materials designed to withstand high pressure and temperature conditions.

Q4: Can Shock Valve Shims from XIAYI be used in different types of shock absorbers?

A4: Yes, XIAYI Shock Valve Shims are compatible with a variety of shock absorbers, but it is recommended to check the specific model compatibility before purchase.

Q5: How do I install the XIAYI Shock Valve Shims?

A5: Installation instructions are typically included with the product, but generally, the shims should be carefully placed within the shock valve assembly according to the manufacturer’s guidelines to ensure optimal performance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!