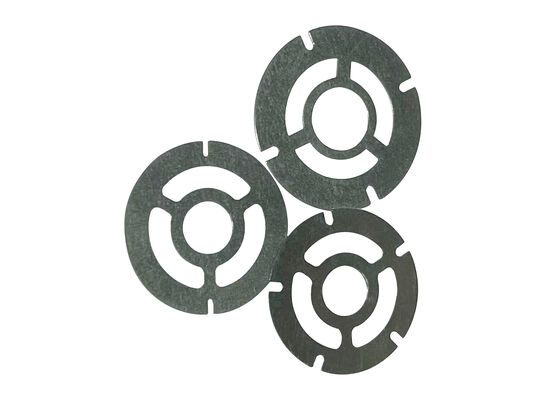

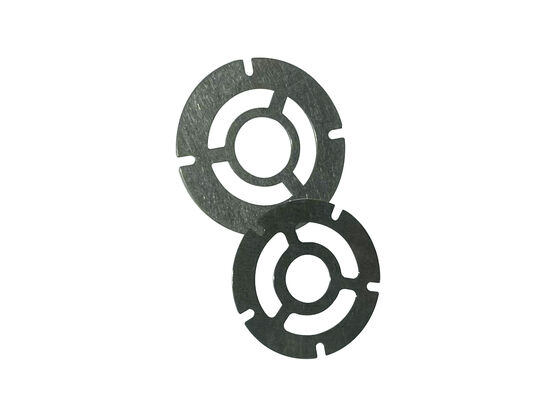

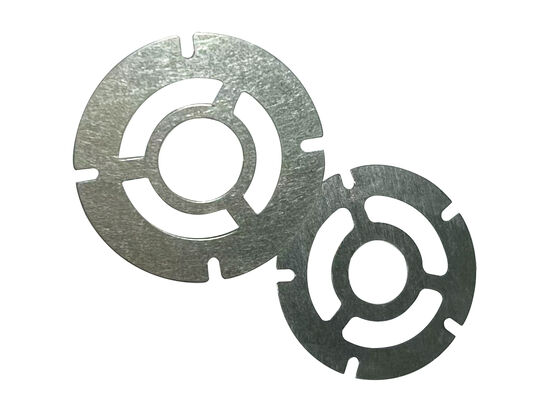

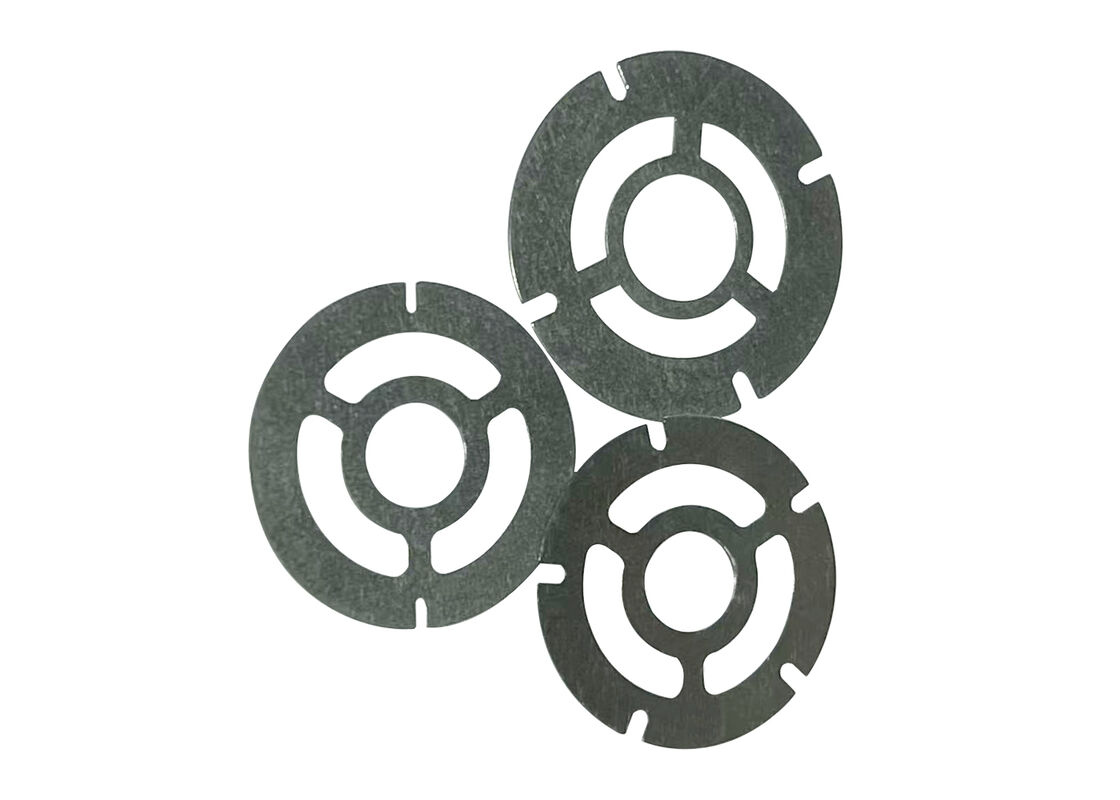

Product Description:

Shock Valve Shims are essential components used in the assembly and performance optimization of shock absorbers. These precision-engineered parts play a critical role in controlling fluid flow within the shock absorber, thereby directly influencing the damping characteristics and overall ride quality of vehicles. As vital Shock Absorber Components, Shock Valve Shims contribute to the fine-tuning of suspension systems, ensuring smoother rides, better handling, and enhanced safety for drivers and passengers alike.

Manufactured using advanced stamping craft, Shock Valve Shims are designed to meet stringent quality standards demanded by both OEM and aftermarket suppliers. The stamping process ensures high precision and repeatability, producing shims that fit perfectly within the shock absorber valve assembly. This meticulous manufacturing approach guarantees that each shim maintains consistent thickness, shape, and surface finish, all of which are critical for optimal shock absorber performance.

The hardness of Shock Valve Shims is carefully controlled within the range of HRC 40-60. This specific hardness range ensures the shims possess the necessary strength and durability to withstand repeated stress and mechanical loads during shock absorber operation. At the same time, the hardness level allows for some flexibility needed for the shims to function effectively in valving applications. Maintaining this hardness range is vital to guarantee long-lasting performance and resistance to wear, which directly impacts the reliability and lifespan of the shock absorber components.

Valving Shims, another term often used interchangeably with Shock Valve Shims, are critical in modulating the flow of hydraulic fluid inside the shock absorber. By adjusting the thickness and material properties of these shims, manufacturers can fine-tune the damping characteristics to meet specific vehicle requirements. This customization capability allows for optimized shock absorber performance across different vehicle types, driving conditions, and user preferences, making these shims indispensable in the suspension system.

Quality inspection is a fundamental part of the production process for Shock Valve Shims. To ensure that each shim meets the highest standards, a comprehensive inspection regime is implemented. This includes Incoming Quality Control (IQC) to verify raw material quality, In-Process Quality Control (IPQC) to monitor manufacturing consistency, Final Quality Control (FQC) to assess the finished products, and Quality Assurance (QA) to oversee the entire production lifecycle. These rigorous inspections guarantee that every batch of shims delivered to customers is defect-free and performs as intended within the shock absorber assembly.

Lead times for sample production of Shock Valve Shims typically range from 10 to 15 days. This timeframe allows manufacturers to produce, inspect, and deliver high-quality samples for evaluation before full-scale production. The relatively short sample time supports rapid development cycles and enables quicker integration of these components into shock absorber manufacturing lines, benefiting both OEMs and aftermarket suppliers looking to reduce time-to-market.

OEM or aftermarket suppliers seeking reliable Shock Absorber Components can depend on these Shock Valve Shims for their superior quality, durability, and precision. Whether used in passenger vehicles, commercial trucks, or specialty machinery, these shims are engineered to meet the diverse demands of modern suspension systems. Their critical role in the valving mechanism ensures that shock absorbers perform consistently under a variety of operating conditions, enhancing vehicle stability and comfort.

In summary, Shock Valve Shims are indispensable elements within the shock absorber assembly that significantly affect the suspension system's damping performance. Manufactured through precision stamping with a controlled hardness of HRC 40-60 and subjected to stringent quality inspections, these Valving Shims offer exceptional reliability and performance. With a sample lead time of just 10-15 days and availability from both OEM and aftermarket suppliers, these shock absorber components provide a dependable solution for enhancing vehicle ride quality and handling characteristics.

Features:

- Product Name: Shock Valve Shims

- Hardness: HRC 40-60 for durability and performance

- Temperature Resistance: Operates efficiently between -40°C to 150°C

- Dimension: OEM specifications to ensure perfect fit

- Manufacturer: Available from OEM or aftermarket suppliers

- Technology: Manufactured using advanced etching or stamping, and line cutting techniques

- Compatible as Washer Shim in shock absorber components

- Designed to work seamlessly with retaining rings in shock absorber assemblies

Technical Parameters:

| Standard |

GB/DIN/JIS/ANSI |

| Surface Finish |

Polished |

| Craft |

Stamping |

| Hardness |

HRC 40-60 |

| Type |

Milling Or Machining |

| Sample Time |

10-15 days |

| Shape |

Round |

| Size |

8mm To 500mm |

| Weight |

Lightweight, Varies By Size |

| Inspection |

IQC, IPQC, FQC, QA |

Applications:

The XIAYI Shock Valve Shims are precision-engineered components designed to enhance the performance and reliability of suspension systems in various vehicles. These valving shims, including trim ring configurations, play a crucial role in fine-tuning the flow characteristics of shock absorbers, ensuring optimal damping and ride quality. Manufactured by OEM or aftermarket suppliers, XIAYI Shock Valve Shims meet rigorous ISO9001:2008 certification standards, guaranteeing consistent quality and durability across all production batches.

One of the primary application occasions for XIAYI Shock Valve Shims is in automotive suspension tuning and repair. Whether you are upgrading the suspension on a high-performance car or replacing worn-out components on a daily driver, these lightweight shims, available in varying sizes, provide the precise valving adjustments needed to achieve the desired ride comfort and handling characteristics. Their construction through milling or machining processes ensures high dimensional accuracy and surface finish, which is essential for maintaining the integrity of the shock valve assembly.

In addition to automotive use, these valving shims are ideal for motorcycles, off-road vehicles, and even industrial machinery where shock absorbers are integral to system performance. The temperature resistance range from -40°C to 150°C enables the XIAYI Shock Valve Shims to perform reliably under extreme environmental conditions, making them suitable for applications in both cold climates and high-heat operating environments.

Another key scenario for using XIAYI Shock Valve Shims is during custom suspension builds and motorsports applications. Enthusiasts and professional tuners rely on the ability to modify the trim ring and shim stack to tailor shock valving precisely to track or terrain conditions. The availability of samples within 10-15 days allows for rapid prototyping and testing, accelerating development cycles and ensuring that the final setup meets performance goals.

Overall, XIAYI Shock Valve Shims offer a versatile and dependable solution for anyone looking to optimize shock absorber valving. Their combination of lightweight design, customizable sizing, and robust temperature resistance makes them a preferred choice in automotive repair shops, racing teams, and OEM manufacturing lines alike. Whether you need to replace existing valving shims or engineer a new trim ring setup, these shims deliver the quality and consistency demanded by modern suspension technology.

Customization:

XIAYI offers customized Shock Valve Shims designed with precision and quality in mind. Our products are manufactured under the ISO9001:2008 certification, ensuring reliable and consistent performance. Utilizing advanced etching or stamping technology combined with line cutting, we provide shims that meet OEM dimensions perfectly.

Our Shock Valve Shims are lightweight yet durable, crafted through expert stamping techniques to guarantee strength and longevity. Available in milling or machining types, these shims are ideal for applications requiring high precision and resilience.

In addition to Shock Valve Shims, XIAYI specializes in Retaining Rings and Metal Ring Gaskets, offering comprehensive solutions for sealing and retention needs. Our Metal Ring Gasket options are engineered to provide excellent sealing performance, complementing the superior quality of our shims and retaining rings.

Packing and Shipping:

Product Packaging: Each set of Shock Valve Shims is carefully packaged in a durable, clear plastic case to prevent any damage during transit. The shims are securely arranged and labeled by size for easy identification and use. The packaging is compact and lightweight, designed to minimize environmental impact while ensuring product safety.

Shipping: We offer reliable and fast shipping options worldwide. Orders are processed within 1-2 business days and shipped via trusted carriers with tracking information provided. Packaging is handled with utmost care to ensure that the Shock Valve Shims arrive in perfect condition. Expedited shipping is available upon request.

FAQ:

Q1: What brand manufactures the Shock Valve Shims?

A1: The Shock Valve Shims are manufactured by the brand XIAYI.

Q2: Are the Shock Valve Shims certified?

A2: Yes, the Shock Valve Shims are certified with IATF16949:2016.

Q3: What materials are used to make XIAYI Shock Valve Shims?

A3: XIAYI Shock Valve Shims are made from high-quality, durable materials designed to withstand high pressure and temperature conditions.

Q4: Can these Shock Valve Shims be used with various shock absorbers?

A4: Yes, XIAYI Shock Valve Shims are designed to be compatible with a wide range of shock absorbers to enhance performance.

Q5: How do Shock Valve Shims improve shock absorber performance?

A5: Shock Valve Shims help regulate the flow of oil within the shock absorber, allowing for better damping control and improved ride comfort.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!