Product Description:

The Shock Valve Shims are essential components designed specifically for use in shock absorber parts and shock absorber components, providing precise control and performance enhancement in suspension systems. These shims play a critical role in regulating the flow of hydraulic fluid within the shock absorber, ensuring smooth and responsive damping characteristics that improve vehicle handling and ride comfort.

One of the standout features of these shock valve shims is their lightweight construction. Despite their robust performance, the shims are engineered to be lightweight, which contributes to the overall efficiency and responsiveness of the shock absorber assembly. This lightweight nature helps reduce the unsprung mass in suspension systems, leading to better vehicle dynamics and improved fuel efficiency.

Durability is another key attribute of the Shock Valve Shims. Manufactured from high-quality materials that withstand rigorous operating conditions, these shims offer exceptional resistance to wear and deformation. This durability ensures long-lasting performance even under extreme stress, making them reliable retaining rings in various shock absorber assemblies.

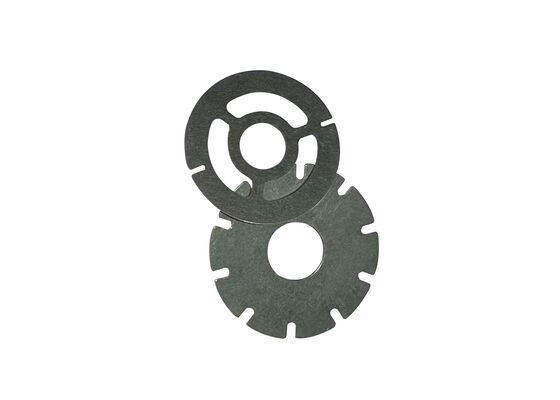

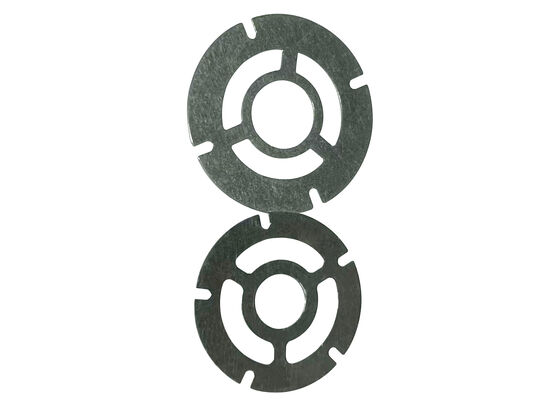

The shims are designed in a round shape, which is standard and optimal for their function within the circular components of shock absorbers. This shape ensures uniform distribution of pressure and consistent sealing performance, which is crucial for maintaining the integrity and functionality of the shock absorber components over time.

Temperature resistance is a critical factor for shock absorber parts, as they often operate under fluctuating and sometimes extreme environmental conditions. These Shock Valve Shims excel with a temperature resistance range from -40°C to 150°C, making them suitable for use in both cold climates and high-temperature environments. This wide temperature tolerance guarantees that the shims maintain their mechanical properties and performance without degradation, regardless of the operating conditions.

Size versatility is another important feature of these shims. Available in a broad range of sizes from 8mm to 500mm, they can be precisely matched to fit a variety of shock absorber designs and applications. Whether for small-scale automotive shocks or larger industrial shock absorbers, the availability of multiple sizes ensures compatibility and optimal performance.

The weight of the Shock Valve Shims varies depending on their size, but they consistently remain lightweight relative to their strength and function. This balance of weight and durability makes them ideal retaining rings for applications where minimizing added mass is crucial without compromising structural integrity.

In summary, the Shock Valve Shims are indispensable shock absorber components that combine lightweight design, exceptional durability, and broad temperature resistance. Their round shape and wide size range allow them to seamlessly integrate into various shock absorber parts, enhancing the overall efficiency and reliability of suspension systems. As reliable retaining rings, these shims contribute significantly to the performance and longevity of shock absorbers, making them a preferred choice for automotive and industrial applications alike.

Features:

- Product Name: Shock Valve Shims

- Technology: Etching or Stamping, Line Cutting

- Inspection Processes: IQC, IPQC, FQC, QA

- Craft: Stamping

- Features: Lightweight and Durable

- Shape: Round

- Ideal for use as Valving Shims in Shock Absorber Components

- Precision-engineered Shock Valve Shims for optimal performance

Technical Parameters:

| Size |

8mm To 500mm |

| Craft |

Stamping |

| Inspection |

IQC, IPQC, FQC, QA |

| Technology |

Etching Or Stamping, Line Cutting |

| Shape |

Round |

| Type |

Milling Or Machining |

| Hardness |

HRC 40-60 |

| Surface Finish |

Polished |

| Standard |

GB/DIN/JIS/ANSI |

| Weight |

Lightweight, Varies By Size |

Applications:

The XIAYI Shock Valve Shims are precision-engineered components designed to enhance the performance and reliability of various mechanical systems. Manufactured by trusted OEM or aftermarket suppliers, these shims meet stringent quality standards, including ISO9001:2008 certification, ensuring consistent excellence in every batch. With a hardness rating of HRC 40-60, these shims provide exceptional durability and wear resistance, making them ideal for high-stress applications.

One of the primary application occasions for XIAYI Shock Valve Shims is in the assembly and maintenance of retaining rings and metal ring gaskets. These components often require precise spacing and alignment to function correctly, and the shock valve shims serve as critical spacers that help absorb impact, reduce vibration, and maintain optimal valve clearances. This makes them indispensable in automotive, industrial machinery, and heavy equipment sectors where retaining rings are commonly used to secure components on shafts or housings.

The versatility of XIAYI Shock Valve Shims extends to various scenarios involving temperature fluctuations, as they can reliably operate within a temperature range of -40°C to 150°C. This temperature resistance ensures that the shims maintain their structural integrity and performance even in extreme environments, such as in automotive engines, hydraulic systems, and heavy-duty manufacturing processes where metal ring gaskets are exposed to harsh thermal conditions.

Furthermore, these shims conform to multiple international standards, including GB, DIN, JIS, and ANSI, making them compatible with a wide range of machinery and equipment worldwide. This compatibility simplifies procurement and integration for maintenance teams dealing with retaining rings and metal ring gasket assemblies across diverse industries.

For manufacturers and maintenance professionals requiring timely delivery, XIAYI offers sample availability within 10-15 days, facilitating quick evaluation and integration into production lines or repair operations. The combination of certified quality, robust hardness, broad temperature resistance, and adherence to international standards positions XIAYI Shock Valve Shims as a reliable choice for anyone working with retaining rings and metal ring gaskets in demanding mechanical applications.

Customization:

XIAYI offers high-quality Shock Valve Shims customized to meet your specific requirements. As certified by IATF16949, our products ensure exceptional reliability and performance. Manufactured using advanced stamping craft, our Shock Absorber Components undergo precise etching or stamping and line cutting technologies to achieve superior accuracy and durability.

We provide a polished surface finish that enhances the overall quality and functionality of the Shock Absorber Components. Our size range spans from 8mm to 500mm, allowing for versatile applications across various shock absorber designs.

With a sample preparation time of just 10-15 days, XIAYI is committed to delivering efficient and tailored Shock Absorber Components to support your production needs.

Support and Services:

Product Technical Support and Services for Shock Valve Shims include comprehensive assistance to ensure optimal performance and longevity of your shock absorbers. Our support team provides expert guidance on the correct selection, installation, and maintenance of valve shims to match your specific shock tuning requirements.

We offer detailed technical documentation, including installation manuals and tuning guidelines, to help you achieve the desired damping characteristics. Additionally, our specialists are available to troubleshoot any issues related to shim wear, valve compatibility, or performance inconsistencies.

For service, we recommend regular inspection and replacement of valve shims as part of your shock maintenance routine to maintain consistent shock performance. Customized shim packages and upgrades are also available for advanced tuning applications.

Our commitment is to provide reliable technical support and high-quality products that enhance the handling and durability of your suspension system.

Packing and Shipping:

Product Packaging and Shipping for Shock Valve Shims

Each set of Shock Valve Shims is carefully packaged to ensure protection during transit. The shims are securely placed in a compact, durable plastic container that prevents bending or damage. This container is then enclosed in a sturdy cardboard box with cushioning materials to absorb any shocks or vibrations.

We offer multiple shipping options including standard, expedited, and express delivery to accommodate your needs. All orders are processed promptly and shipped via reliable carriers to ensure timely arrival. Tracking information will be provided once your order is dispatched.

For bulk orders, customized packaging solutions and freight shipping options are available upon request. Please contact our customer service team for more details.

We take every precaution to ensure your Shock Valve Shims arrive in perfect condition and ready for use.

FAQ:

Q1: What brand manufactures the Shock Valve Shims?

A1: The Shock Valve Shims are manufactured by the brand XIAYI.

Q2: Are the Shock Valve Shims certified for quality?

A2: Yes, the Shock Valve Shims are certified with IATF16949, ensuring high-quality standards.

Q3: What materials are used in the XIAYI Shock Valve Shims?

A3: The XIAYI Shock Valve Shims are made from durable and high-quality materials designed to withstand pressure and provide long-lasting performance.

Q4: Can these Shock Valve Shims be used in different types of shock absorbers?

A4: Yes, XIAYI Shock Valve Shims are designed to be compatible with a variety of shock absorber models, but it is recommended to check the specifications for your specific application.

Q5: How do the Shock Valve Shims affect the performance of a shock absorber?

A5: Shock Valve Shims from XIAYI help regulate the flow of hydraulic fluid within the shock absorber, improving damping performance and ride comfort.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!